TFS 200 ALD tool for research

TFS 200 ALD tool for research

Plasma, particle and high aspect ratio ALD

Direct and remote plasma-enhanced deposition (PEALD) is available in the TFS 200 as a standard option. The plasma is capacitively-coupled (CCP), which is the industry standard of today. The

TFS 200 can coat planar objects, particles, porous bulk materials and complex 3D shapes with very high aspect ratio features. Depending on the substrate, a selection of three standard reaction chamber designs are available, as well as any customized designs our customers’ cases might require.

Performance highlights

- Down to 100 nm particle coating in fluidized bed reactor option

- Direct and remote capacitive coupled plasma available for plasma-enhanced ALD (PEALD) option

- Process cycle time customarily less than 2 seconds. In specific cases even less than 1 second (thickness uniformity variation < ±1% for, e.g., Al2O3 on 200 mm wafer).

- High Aspect Ratio (HAR) available for structures with deep trenches and porous substrates

- Hot source versatility, up to 500 °C setup as standard option

- High speed and capacity data logging and trend tools for human machine interface (HMI)

- Cold-wall vacuum chamber for rapid heating and cooling

- Auxiliary entry ports in vacuum chamber enable plasma, in situ diagnostics etc.

- Hot-wall reaction chamber for uniform substrate temperature and to prevent precursor condensation and secondary reactions

- Three different reaction chamber designs, as well as any customized design

- Load lock available for rapid substrate change and integration with other equipment

- Clean-room compatible.

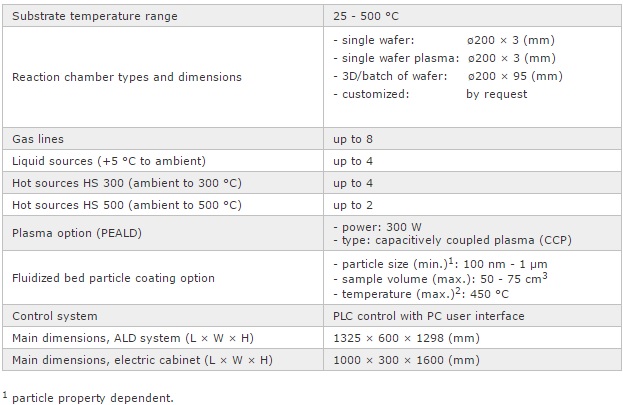

Technical specifications:

labexpert-logo.png)