TFS 200R Thin Film System TFS 200R for spatial ALD research

TFS 200R Thin Film System TFS 200R for spatial ALD research

In the TFS 200R, the flexible substrate is fixed on a rotating cylinder within the reaction chamber. The cylinder itself is surrounded by a number of linear nozzles, each creating an isolated gas region over the full width of the substrate. As the cylinder is rotated, the substrate passes through different gas regions and is coated.

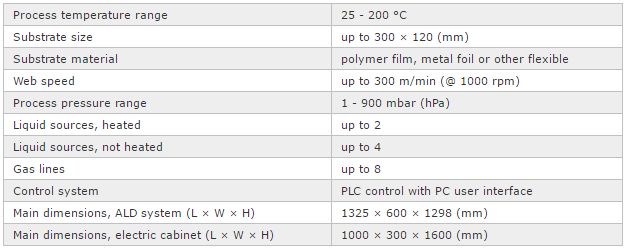

The Beneq TFS 200R, with its robust and modular structure, is designed to meet both industrial standards and the flexibility requirements of research today. Precursor containers are conveniently small, and they can be easily changed. Depending on the process needs, the TFS 200R can be equipped with up to 2 heated sources, type HS 80 and/or HS 180. Additionally, the system can be equipped with up to 8 gas lines and up to 4 liquid sources.

Performance highlights

- Thin film deposition rate up to 100 nm/min

- Moving substrate, web speed up to 300 m/min

- High speed and capacity data logging as well as trend tools for human machine interface (HMI).

- Cold-wall vacuum chamber for rapid heating and cooling

- Auxiliary entry ports in vacuum chamber enable in situ diagnostics etc

- Heated substrate and gas feed assembly for uniform substrate temperature and prevention of precursor condensation

- Class 100 (ISO 5) clean-room compatibility

- The precursor source configuration allows for easy, inert change of precursors

Technical specifications:

labexpert-logo.png)