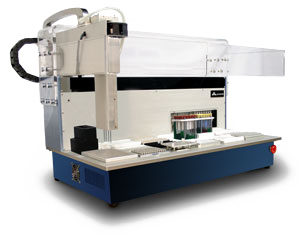

VERSA Cap Piercing Workstation

VERSA Cap Piercing Workstation

The need for automation of sample preparation of biologically hazardous samples poses challenges for many robotic workstations often requiring manual capping and uncapping steps which expose workers to potentially hazardous substances or risk contamination of samples. Aurora’s VERSA™ Cap Piercing Workstation is an automated liquid handling workstation designed to perform closed tube sampling and automate sample transfer protocols. By automating sample preparation processes laboratories can minimize human error, increase sample turnaround time and prevent repetitive motion injuries arising from de-capping and re-capping sample containers. Aurora’s VERSA™ Cap Piercing Workstation provides an automated mechanism for piercing capped source containers (including tubes and vials) and performing sample transfer into a variety of target containers. The underlying versatility of the workstation allows it to perform many generic liquid handling tasks such as serial dilution, plate reformatting and plate replication. As laboratories are expected to do more with less, implementing and utilizing the VERSA™ Cap Piercing Workstation will result in quantifiable work-flow improvements.

- Removes the need to manually cap/uncap tubes

- Contains potentially hazardous or volatile samples in their original container

- Allows automation of protocols requiring sealed containers

- Supports diverse tube types for maximum flexibility

- Simplifies workflow and decreases turnaround time by removing the need for uncapping

- On-deck ultrasonic wash station eliminates carryover between samples

- High precision reduces variability and increases reproducibility

- High throughput solution to process multiple samples in parallel

labexpert-logo.png)